Engineering Leadership Development Program (ELDP)

Lockheed Martin

In this series of projects, you’ll find videos of an omnidirectional pneumatic gripper that was designed for a Lifecycle Project co-hosted by Cornell University and the ELDP Program. While I cannot show the other projects I’ve completed at Lockheed Martin, here, you will find a summary of all the skills I have acquired during my 5 years at Lockheed with images depicted related topics to those I have worked on.

Lifecycle Project (LCP)

Collaborated with a multi-discipline team across 5 states and 2 countries to deliver a soldier retrieval system.

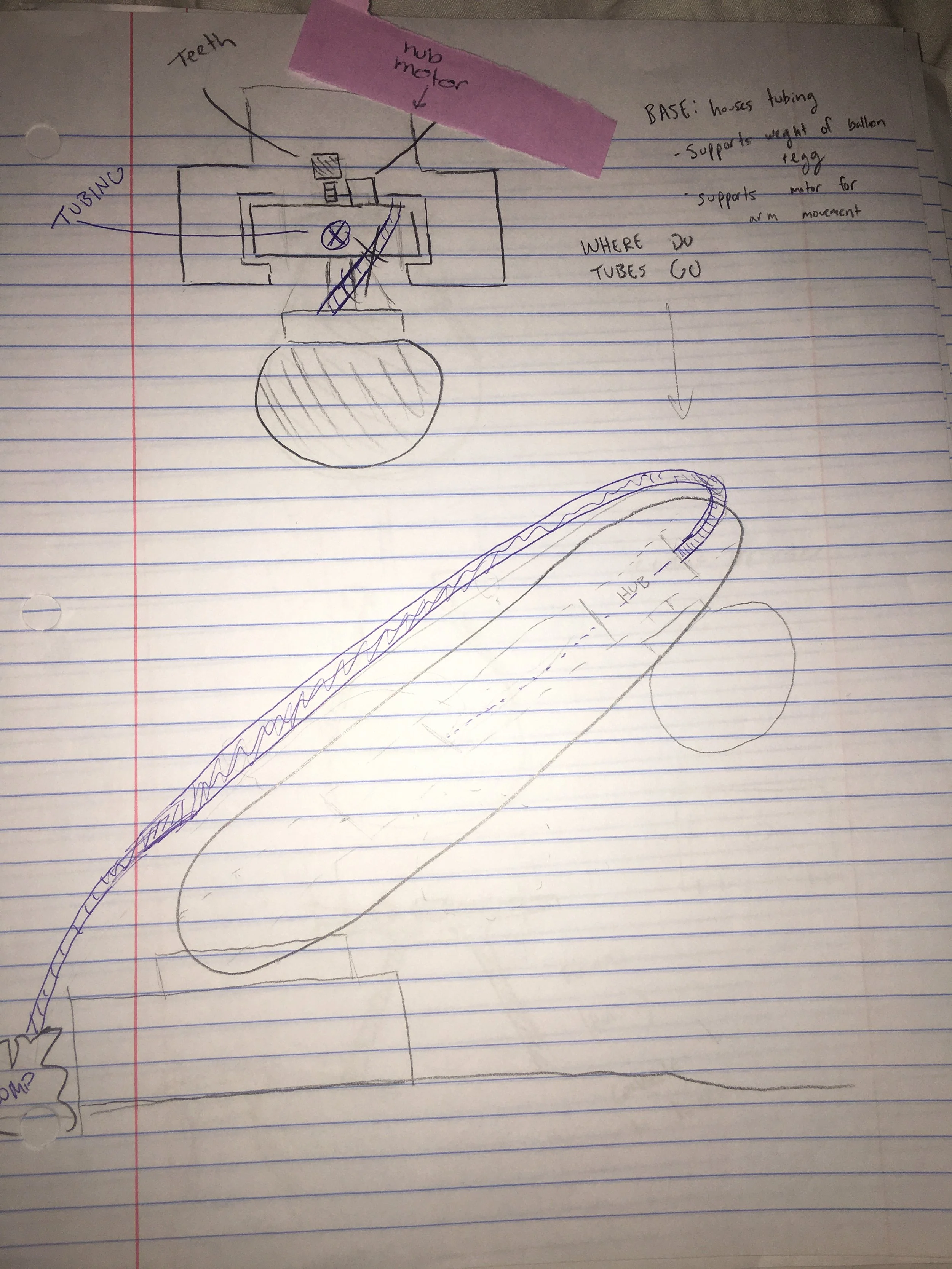

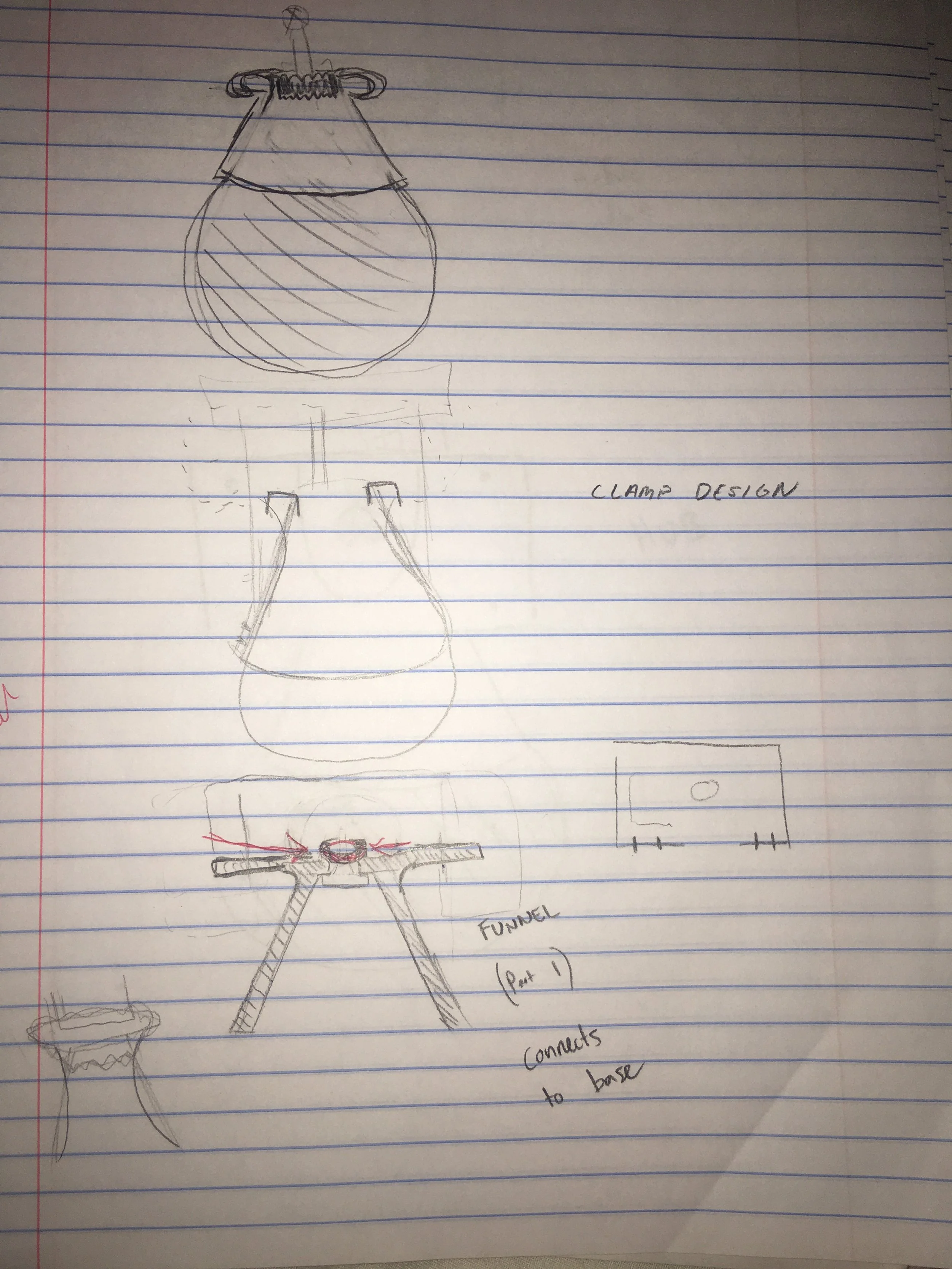

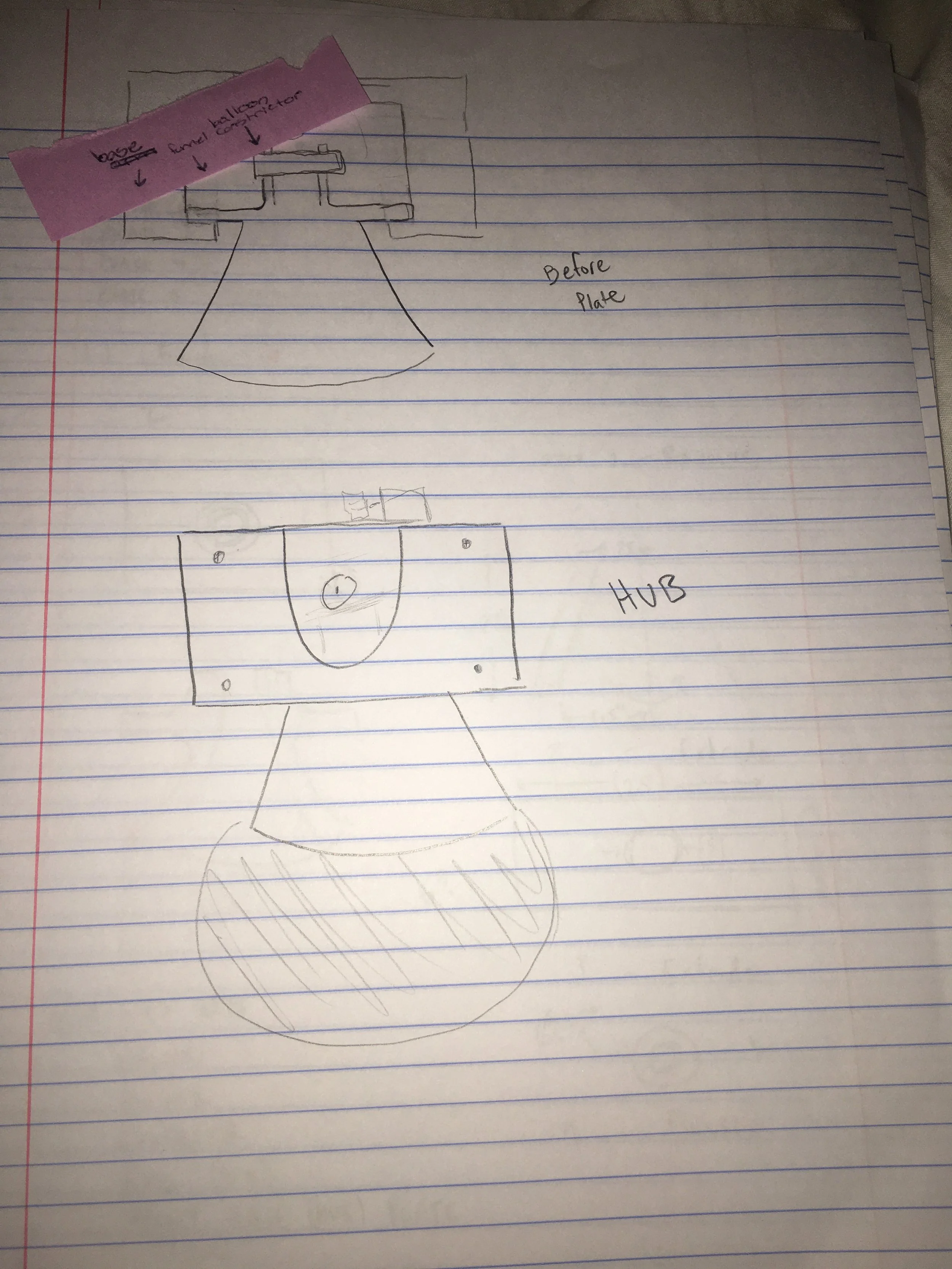

Authored a multi-volume proposal, presented status at regular design reviews as well as bi-weekly demonstrations while designing an omnidirectional pneumatic gripper.

Mentors insisted we change our design because there was “No way it could possibly work” and we floored them with a perfect track record during testing phases and demonstration day.

Won the award for “Most Ingenious Design” and a high-five for sticking with our guts.

Engineering Leadership Development Program (ELDP)

ELDP is a 3 year program which pushes beginner level engineers to their limits to prepare us for taking up the mantle as the future leaders of the industry.

We participate in three Leadership Development Conferences (LDC), a Technical Development Curriculum (TDC) co-hosted by Cornell University, a Lifecycle Project (shown above), Volunteering and Outreach, on top of a rotational program working 9-12 months in different sectors of the work force. It is most commonly and endearingly referred to as “The most fun you never want to have again!”

Below, Paige Tarlecki awards me with my graduation plaque, as well as the superlative for “Worst Puns.” (Clearly they meant best).

Additionally, I was featured in the Women in Engineering Day article on Lockheed Martin’s homepage, from my time teaching girls the importance of coding (3rd image from the left).

Lockheed Martin Projects

Developed a seismic mount for an earthquake-prone, safety-critical facility and verified safety by utilizing modal analysis and response spectrum functions in ANSYS.

Designed a 3D-printed fixture in Creo to increase efficiency and reduce cost of testing.

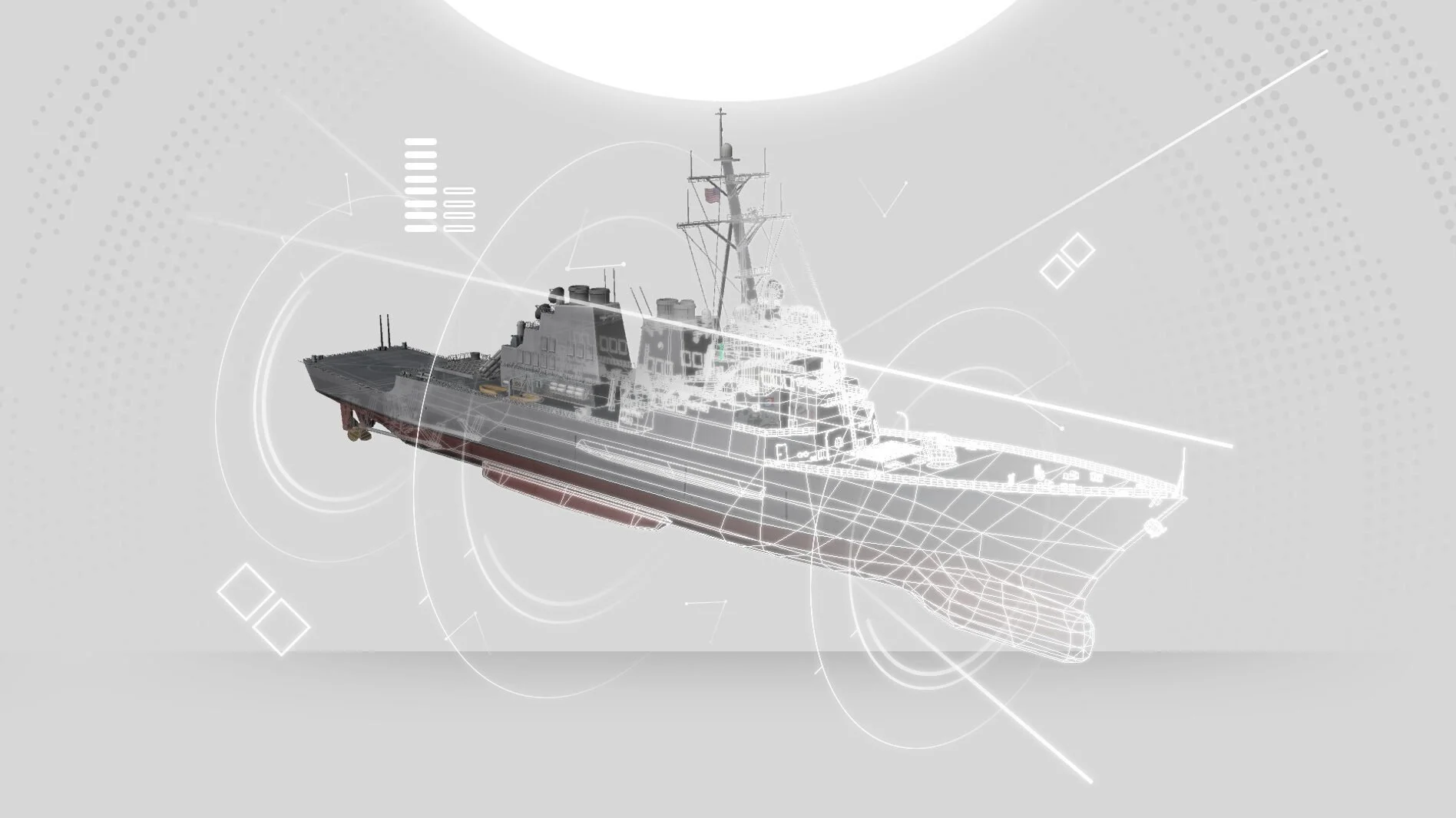

Conducted regression testing, isolated issues, submitted problem reports, reproduced reported issues, and fixed potential system malfunctions during AEGIS Ship test shots

Replicated A-Spec system design in use case, requirement, and activity diagrams by interpreting the proposal documentation, working directly with technical leads, and presenting at weekly demonstrations to represent the architecture of the new fleet.

Coordinated and negotiated design updates with dependent programs.

Automated a script which cut 30 hours off generating technical reviews.